Exploring Hydrogen Leak Detection: Parts, Tests, and Major Players

December 27, 2023 | by hydrogen-leakdetector.com

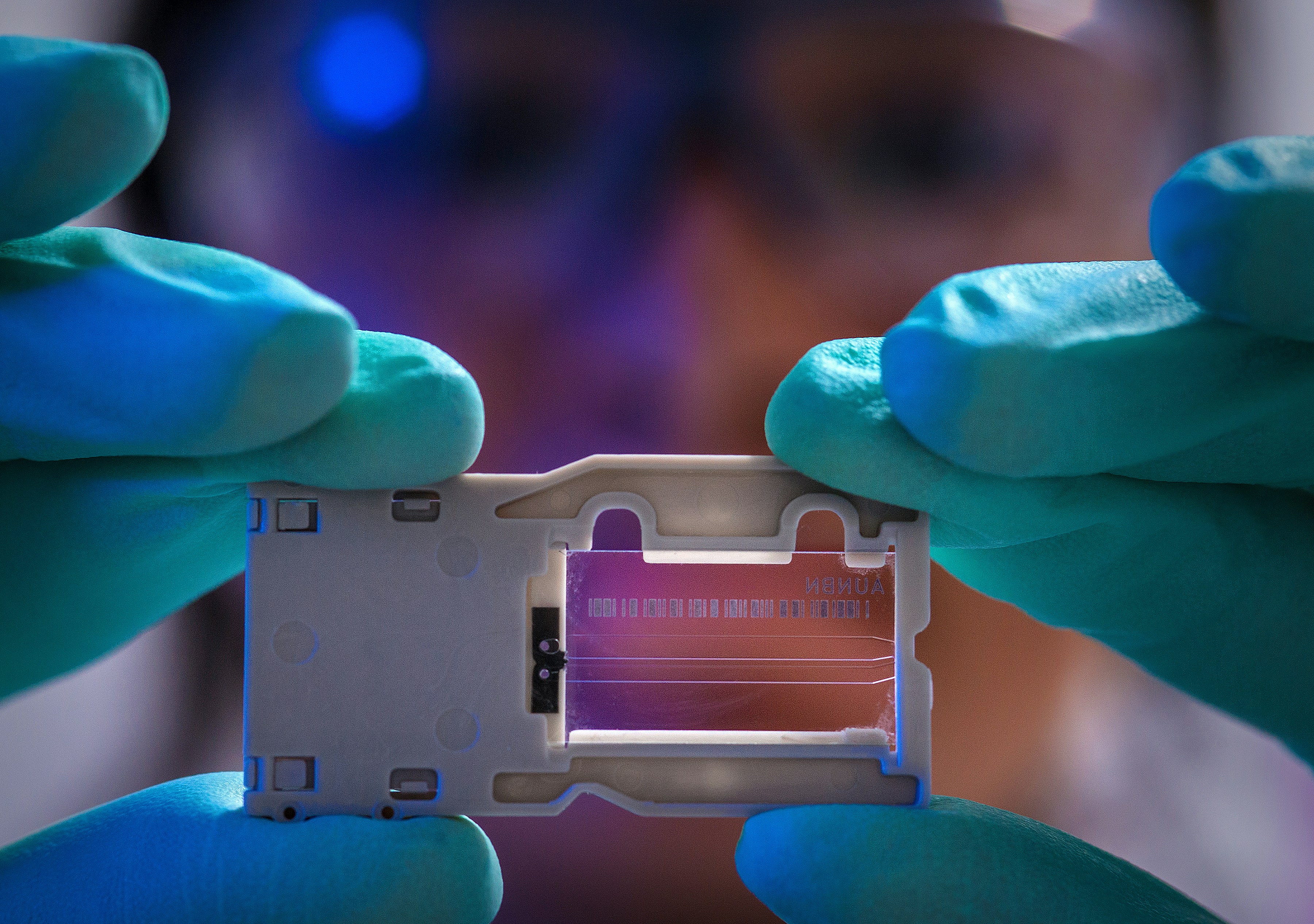

Photo by Pop & Zebra on Unsplash

Photo by Pop & Zebra on Unsplash Hydrogen leak detection is a critical aspect of ensuring safety and efficiency in various industries. Whether it’s at the industrial level or examining individual parts and consumables, the detection of hydrogen leaks plays a crucial role in preventing accidents and optimizing operations. In this blog post, we will delve into the different parts to be tested, the types of tests involved, and highlight major players in the industry, including ATEQ.

Parts to be Tested

Hydrogen leak detection involves examining various parts and components to identify potential leaks. Some of the key parts that undergo testing include:

- Tanks and storage systems: These are crucial components where hydrogen is stored, and any leaks can pose significant risks. Regular testing ensures the integrity of these systems.

- Pipelines and fittings: The network of pipelines and fittings that transport hydrogen need to be thoroughly inspected to prevent leaks that may compromise safety and efficiency.

- Valves and regulators: These control the flow of hydrogen and need to be tested to ensure proper functioning and prevent any leaks.

- Seals and gaskets: These small yet vital components are often prone to wear and tear, making it essential to check for leaks and replace them if necessary.

Types of Tests

Hydrogen leak detection involves a range of tests to identify and quantify leaks accurately. Some common types of tests include:

- Visual inspection: This initial step involves a thorough visual examination of the parts and components for any visible signs of leakage, such as cracks, corrosion, or damaged seals.

- Pressure testing: This method involves pressurizing the system or the component with hydrogen and monitoring for any drop in pressure, indicating the presence of a leak.

- Helium leak testing: Helium, being a small molecule, can easily penetrate even the tiniest leaks. This method involves introducing helium gas into the system and using a specialized detector to identify any leaks.

- Bubble testing: This simple yet effective method involves applying a soapy solution to the suspected area and observing for the formation of bubbles, indicating the presence of a leak.

- Ultrasonic testing: This non-destructive testing method uses high-frequency sound waves to detect leaks by identifying changes in the ultrasonic wave patterns caused by escaping hydrogen.

Major Players in Hydrogen Leak Detection

ATEQ, a leading provider of leak detection solutions, is one of the major players in the field of hydrogen leak detection. With their expertise and innovative technologies, ATEQ offers a wide range of products and services to ensure accurate and reliable leak detection in various industries.

It is important to choose a trusted and experienced provider when it comes to hydrogen leak detection. Hydrogen leak detection is a critical process that involves testing various parts, utilizing different types of tests, and relying on major players in the industry like ATEQ. By ensuring the integrity of hydrogen systems and components, these tests contribute to the overall safety and efficiency of operations in industries where hydrogen is used.

RELATED POSTS

View all