Understanding Hydrogen Leak Detection: Parts and Tests

December 27, 2023 | by hydrogen-leakdetector.com

Hydrogen leak detection is a critical aspect of ensuring safety and efficiency in various industries. Whether at an industrial level or when examining individual parts and consumables, thorough testing is essential. In this blog post, we will explore the different parts that require testing and the various types of tests involved in hydrogen leak detection.

Parts to be Tested

Hydrogen leak detection involves testing various components and systems to identify any potential leaks. Some of the key parts that require testing include:

- Pipelines and Storage Tanks: The integrity of hydrogen pipelines and storage tanks must be regularly checked for leaks. This ensures the safe transportation and storage of hydrogen.

- Valves and Fittings: Valves and fittings play a crucial role in controlling the flow of hydrogen. Regular testing helps identify any leaks or faulty components.

- Pressure Vessels: Pressure vessels, such as those used in hydrogen fuel cells, need to be tested to ensure they can withstand the high-pressure conditions without any leaks.

- Hydrogen Fuel Cells: Fuel cells are an integral part of hydrogen-powered systems. Testing fuel cells helps identify any leaks or malfunctions that could impact their performance.

- Hydrogen Generators: Hydrogen generators produce hydrogen gas for various applications. Regular testing ensures the generators are functioning optimally and without any leaks.

Types of Tests

Hydrogen leak detection involves different types of tests to accurately identify leaks and ensure the safety of the systems. Some of the commonly used tests include:

- Visual Inspection: Visual inspection involves examining the components for any visible signs of leaks, such as cracks, corrosion, or damaged seals.

- Pressure Decay Test: This test involves pressurizing the system and monitoring the pressure drop over a specific period. A significant pressure drop indicates the presence of a leak.

- Hydrostatic Test: In a hydrostatic test, the system is filled with water or another suitable liquid and pressurized. Any leaks result in the formation of bubbles, indicating the presence of a leak.

- Ultrasonic Testing: Ultrasonic testing uses high-frequency sound waves to detect leaks. The sound waves are directed at the components, and any reflected waves indicate the presence of a leak.

- Gas Chromatography: Gas chromatography involves analyzing the gas mixture for the presence of hydrogen. Any abnormal hydrogen levels can indicate a leak.

Major Actors in Hydrogen Leak Detection

When it comes to hydrogen leak detection, several major actors play a crucial role in developing and implementing effective testing methods. One such prominent player is ATEQ.

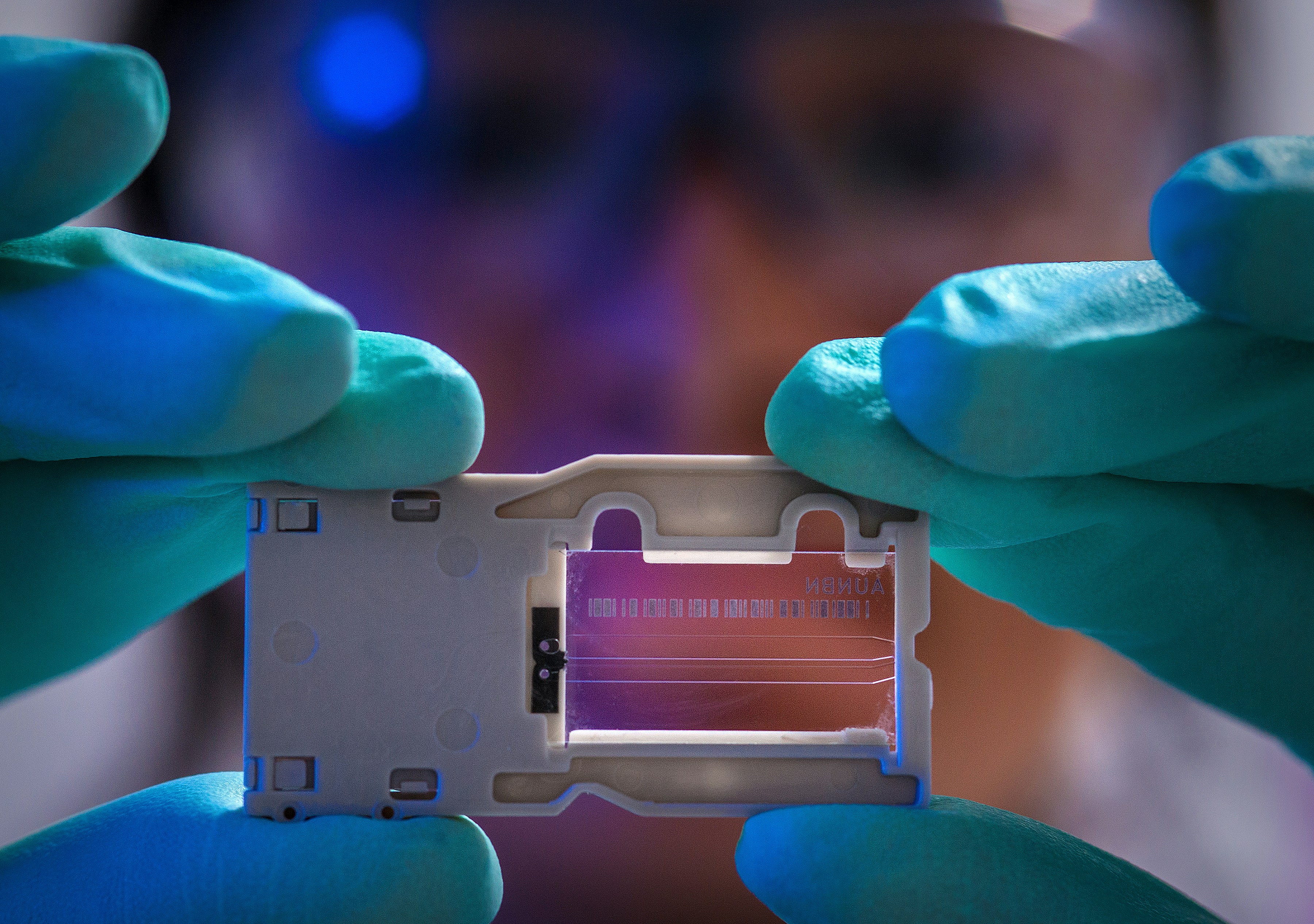

ATEQ is a leading provider of leak testing equipment and solutions. Their expertise in hydrogen leak detection allows industries to ensure the safety and reliability of their systems. ATEQ offers a range of advanced leak testing instruments that utilize innovative technologies to accurately detect hydrogen leaks.

With their cutting-edge equipment, ATEQ enables industries to meet stringent safety standards and regulations. Their solutions cater to various industries, including automotive, aerospace, energy, and more.

In conclusion, hydrogen leak detection is a vital aspect of maintaining safety and efficiency in various industries. By testing different parts and utilizing various testing methods, such as visual inspection, pressure decay tests, and ultrasonic testing, potential leaks can be identified and addressed promptly. With the support of major actors like ATEQ, industries can ensure the reliability and safety of their hydrogen systems.

RELATED POSTS

View all