All blog posts

Explore the world of design and learn how to create visually stunning artwork.

What is the impact of the PED 2014/68/EU directive on a production line?

February 16, 2024 | by hydrogen-leakdetector.com

Hydrogen Leak Detection: Monitoring and Testing

December 27, 2023 | by hydrogen-leakdetector.com

Photo by Daan Mooij on Unsplash

Photo by Daan Mooij on Unsplash A Comprehensive Guide to Hydrogen Leak Detection Testing

December 27, 2023 | by hydrogen-leakdetector.com

Photo by Pop & Zebra on Unsplash

Photo by Pop & Zebra on Unsplash Exploring Hydrogen Leak Detection: Parts, Tests, and Major Players

December 27, 2023 | by hydrogen-leakdetector.com

Photo by Daan Mooij on Unsplash

Photo by Daan Mooij on Unsplash The Essential Guide to Hydrogen Leak Detection Testing

December 27, 2023 | by hydrogen-leakdetector.com

Understanding Hydrogen Leak Detection: Parts and Tests

December 27, 2023 | by hydrogen-leakdetector.com

The adoption of the European Directive PED 2014/68/EU within a production line entails significant technical and operational changes aimed at ensuring that all pressure equipment meets the highest safety and quality standards. Here are the key technical and operational aspects impacted by the directive:

DESIGN AND ENGINEERING

- Incorporating safety from the design phase: The directive mandates that safety considerations be integrated from the earliest stages of equipment design. This involves adhering to recognized design standards and conducting risk assessments to identify and mitigate potential hazards. Engineers must therefore consider PED requirements when developing new products, which may necessitate specific training and the adoption of new design practices.

MATERIALS AND MANUFACTURING

- Material selection: The PED sets stringent criteria for the selection of materials used in the manufacture of pressure equipment, focusing on traceability, quality, and the materials’ resistance to the intended operating conditions. Manufacturers must ensure that the chosen materials are suitable for their intended use and meet the required standards for strength and durability.

- Manufacturing processes: Manufacturing methods must be adapted to meet the high standards of quality and safety imposed by the PED. This could lead to the implementation of new welding, assembly, and surface treatment techniques, as well as the adoption of stricter quality controls throughout the production process.

CONTROLS AND TESTING

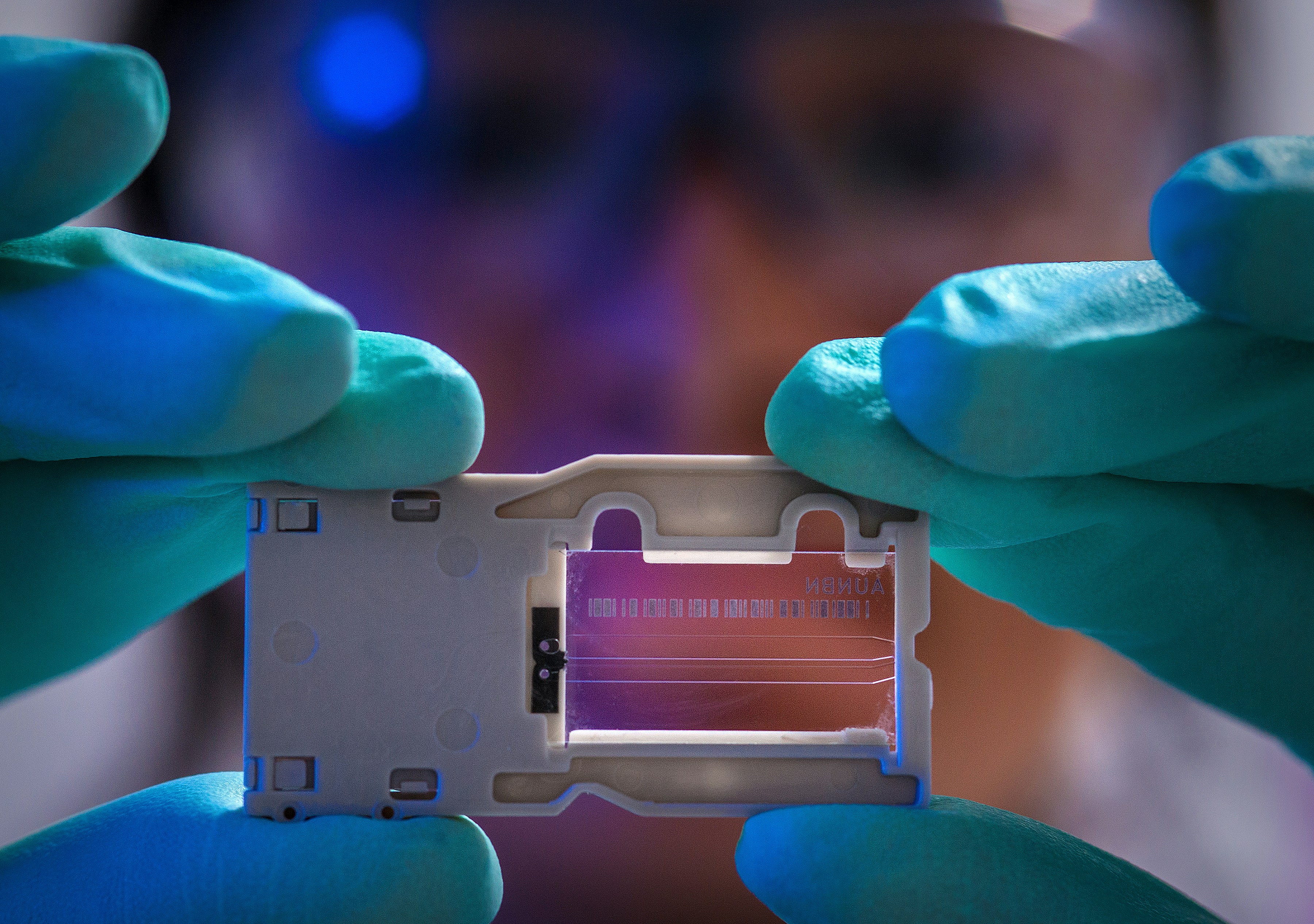

- Enhanced inspections and testing: The directive requires specific controls and tests to be conducted at various stages of production to verify equipment compliance. Pressure testing, for example, must be carried out on each piece to ensure its leak-tightness and mechanical strength. This means that production lines must be equipped to perform these tests, potentially necessitating investments in new testing and measurement equipment.

DOCUMENTATION AND TRACEABILITY

- Comprehensive documentation: The PED demands detailed documentation for each piece of equipment manufactured, including design, materials used, manufacturing procedures, and test results. This documentation must be available for inspection by competent authorities and customers, thus ensuring total transparency and full traceability of the manufacturing process.

The integration of the PED 2014/68/EU directive into a production line requires considerable adjustments from the design phase through to manufacturing and final testing. These changes ensure that manufactured pressure equipment is not only compliant with European safety and quality standards but also meets customer expectations in terms of reliability and performance. For manufacturers, this represents a commitment to excellence that can translate into a significant competitive advantage in the market.