The Essential Guide to Hydrogen Leak Detection Testing

December 27, 2023 | by hydrogen-leakdetector.com

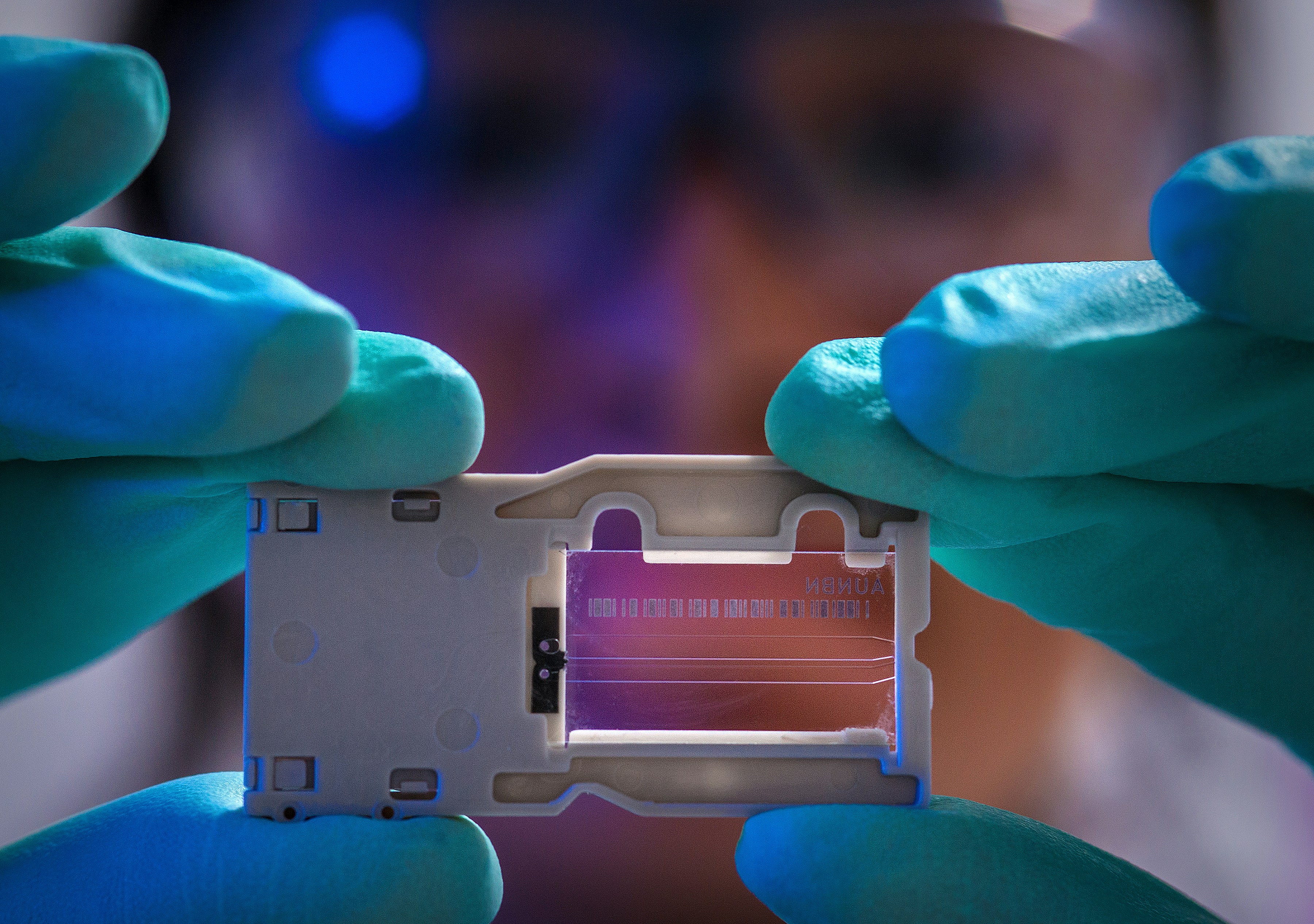

Photo by Daan Mooij on Unsplash

Photo by Daan Mooij on Unsplash Hydrogen leak detection is a critical process in various industries, ensuring safety and efficiency in the handling and storage of hydrogen. Whether it’s at an industrial level or for individual parts and consumables, thorough testing is essential. In this blog post, we will explore the different parts that need to be tested and the various types of tests involved in hydrogen leak detection.

Parts to be Tested

When it comes to hydrogen leak detection, several parts need to be tested to ensure the integrity of the system. These parts include:

- Tanks and containers: Hydrogen storage tanks and containers must be tested to identify any leaks that could compromise safety.

- Piping systems: The piping systems that transport hydrogen from one point to another should be thoroughly checked for any leaks.

- Valves and fittings: Valves and fittings play a crucial role in controlling the flow of hydrogen. Regular testing helps identify any leaks or malfunctions.

- Seals and gaskets: Proper sealing is essential to prevent hydrogen leaks. Testing seals and gaskets ensures their effectiveness.

- Connectors and couplings: Connectors and couplings are potential areas for leaks. Testing these components helps identify any issues.

Types of Tests

Hydrogen leak detection involves various types of tests, each serving a specific purpose. Some common types of tests include:

- Visual Inspection: This is the first step in leak detection, involving a visual examination of the parts and components for any signs of leakage, such as discoloration or damage.

- Pressure Decay: In this test, the system is pressurized, and the pressure drop over time is measured. A significant drop indicates the presence of a leak.

- Hydrostatic Testing: This test involves filling the system with water and pressurizing it to check for leaks. Any leaks will be visible as bubbles.

- Ultrasonic Testing: Ultrasonic waves are used to detect leaks by measuring the sound waves produced by escaping hydrogen.

- Gas Tracer Testing: A tracer gas, such as helium, is introduced into the system. If there is a leak, the tracer gas will escape and can be detected using specialized equipment.

Major Actors in Hydrogen Leak Detection

When it comes to hydrogen leak detection, several major actors provide testing solutions and equipment. One such prominent player in the industry is ATEQ.

ATEQ is a leading manufacturer of leak testing equipment and solutions, including hydrogen leak detection systems. Their advanced technology and expertise make them a trusted choice for industries that rely on hydrogen.

In conclusion, hydrogen leak detection is crucial for maintaining safety and efficiency in various industries. By testing the different parts and utilizing various types of tests, potential leaks can be identified and addressed promptly. With trusted actors like ATEQ providing reliable testing solutions, industries can ensure the integrity of their hydrogen systems and operations.

RELATED POSTS

View all